A860 WPHY 60 管帽

尺寸 | 1/2″~72 “ |

壁厚等级 | 2mm – 50mm / SCH5, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

制造标准

| ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. | |

材质 | 20#, 20G,Q235-A, ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70 |

16Mn, ASTM A420 WPL3, A420 WPL6 | |

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91, WB36, 12CrMo, 15Cr5Mo, 1Cr5Mo, 12Cr1MoV |

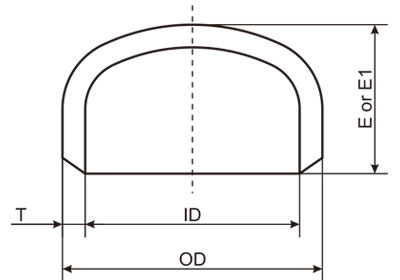

Nominal Pipe Size | Outside diameter at Bevel | Length(2) | Limiting wall Thickness for Length | Length(3) |

1/2 | 21.3 | 25.4 | 4.6 | 25.4 |

3/4 | 26.7 | 25.4 | 3.8 | 25.4 |

1 | 33.4 | 38.1 | 4.6 | 38.1 |

1-1/4 | 42.2 | 38.1 | 4.8 | 38.1 |

1-1/2 | 48.3 | 38.1 | 5.1 | 38.1 |

2 | 60.3 | 38.1 | 5.6 | 44.4 |

2-1/2 | 73.0 | 38.1 | 7.1 | 50.8 |

3 | 88.9 | 50.8 | 7.6 | 63.5 |

3-1/2 | 101.6 | 63.5 | 8.1 | 76.2 |

4 | 114.3 | 63.5 | 8.6 | 76.2 |

5 | 141.3 | 76.2 | 9.7 | 88.9 |

6 | 168.3 | 88.9 | 10.9 | 101.6 |

8 | 219.1 | 101.6 | 12.7 | 127.0 |

10 | 273.1 | 127.0 | 12.7 | 152.4 |

12 | 323.9 | 152.4 | 12.7 | 177.8 |

14 | 355.6 | 165.1 | 12.7 | 190.5 |

16 | 406.4 | 177.8 | 12.7 | 203.2 |

18 | 457.2 | 203.2 | 12.7 | 228.6 |

20 | 508.0 | 228.6 | 12.7 | 254.0 |

22 | 558.8 | 254.0 | 12.7 | 254.0 |

24 | 609.6 | 266.7 | 12.7 | 304.8 |

26 | 660.4 | 266.7 | ||

28 | 711.2 | 266.7 | ||

30 | 762.0 | 266.7 | ||

32 | 812.8 | 266.7 | ||

34 | 863.4 | 266.7 | ||

36 | 914.4 | 266.7 | ||

38 | 965.2 | 304.8 | ||

40 | 1016.0 | 304.8 | ||

42 | 1066.8 | 304.8 | ||

44 | 1117.6 | 342.9 | ||

46 | 1168.4 | 342.9 | ||

48 | 1219.2 | 342.9 |

小于等于36“的盖子壁厚符合ANSI B36.10规范。大于等于38”的盖子符合XS规范对于36英寸的壁厚,这些是

Wellgrow的标准,因为没有为如此大的壁厚设定国际公认的标准。

(1) 这些盖子的形状应为椭圆形,并应符合ASME锅炉及压力容器规范中给出的形状要求。

(2) 长度E适用于厚度不超过“长度E的限制壁厚”一栏中给出的厚度。

(3) 长度E1适用于大于NPS 24及以下的“极限壁厚”一栏中给出的厚度。对于NPS 26及以上的,长度E1应

由制造商和买方达成协议。